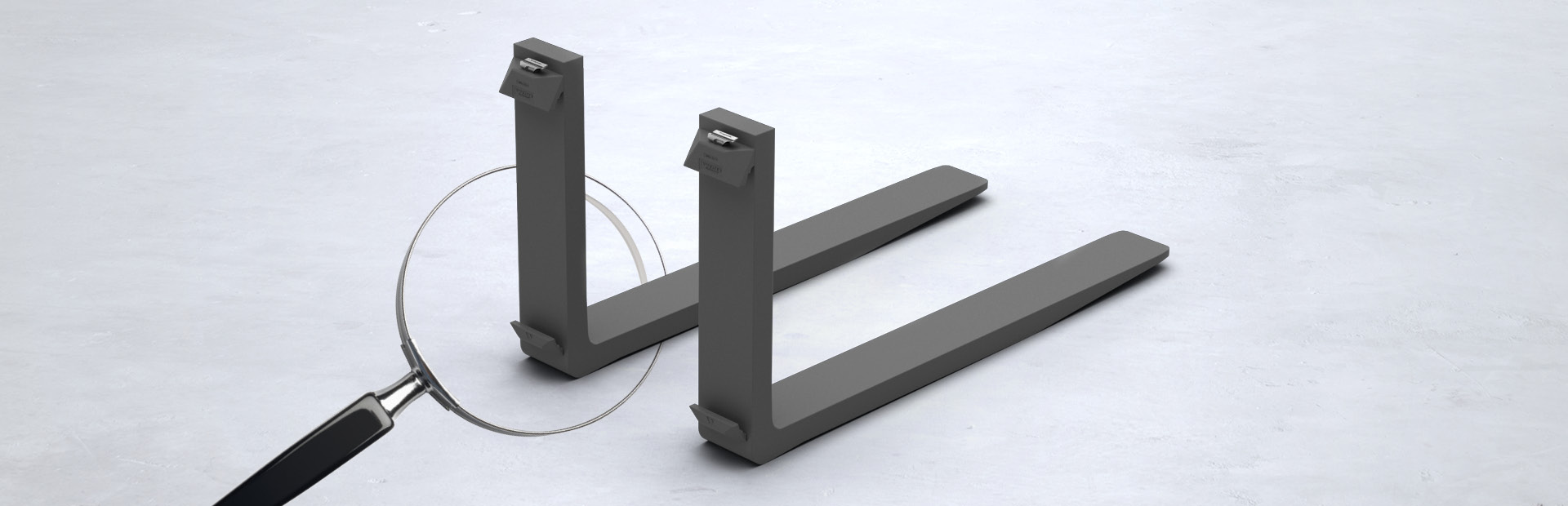

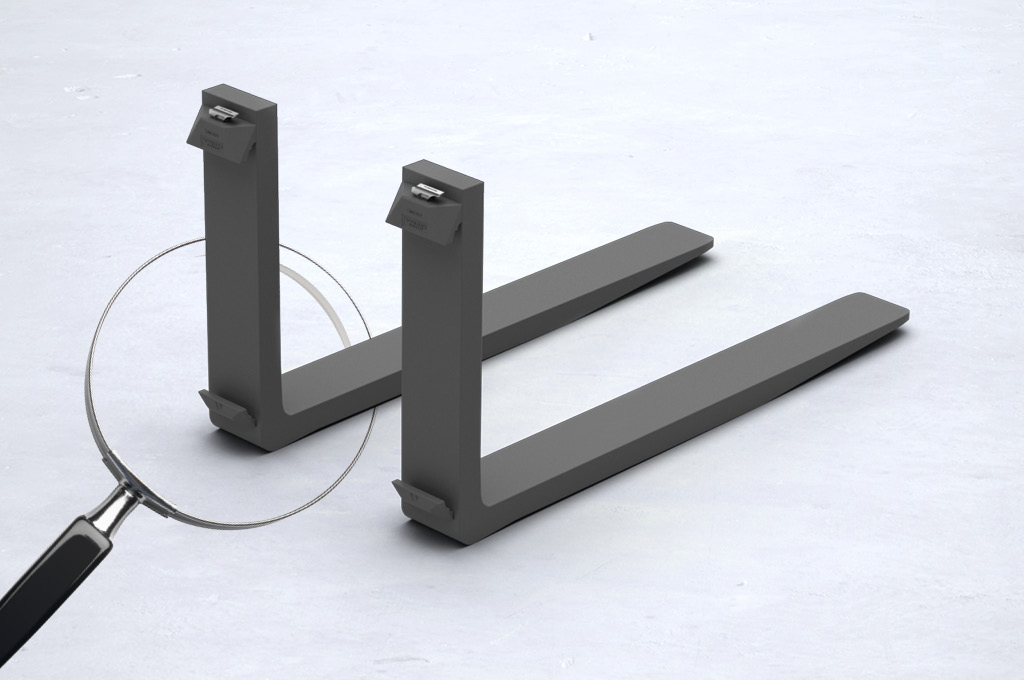

Forks are safety items. Therefore, highest attention should be paid to a regular inspection of forks.

Note: The use of safe forks, which are in perfect condition, is not only your duty but also an advantage. Working safely means working at lower costs! Ensuring safety at all times prevents disturbance and guarantees that your equipment is always at your disposal.

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/f/e/csm_navigation_fork_extensions_689922e615.png)

Share: