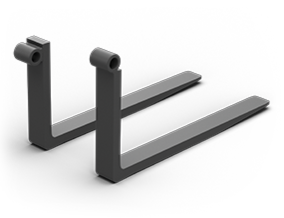

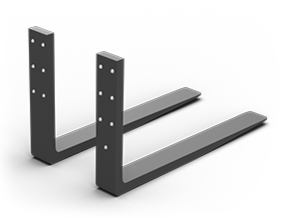

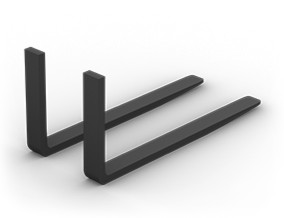

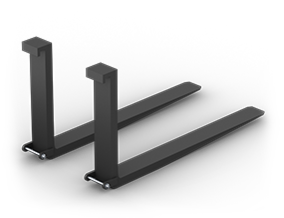

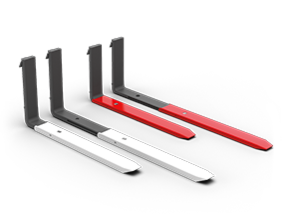

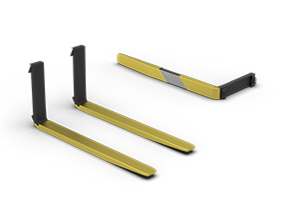

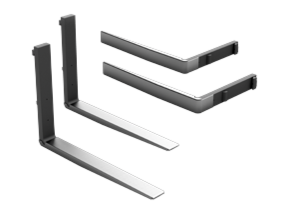

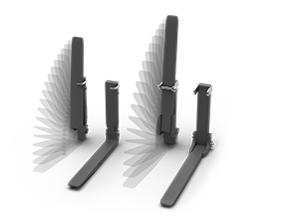

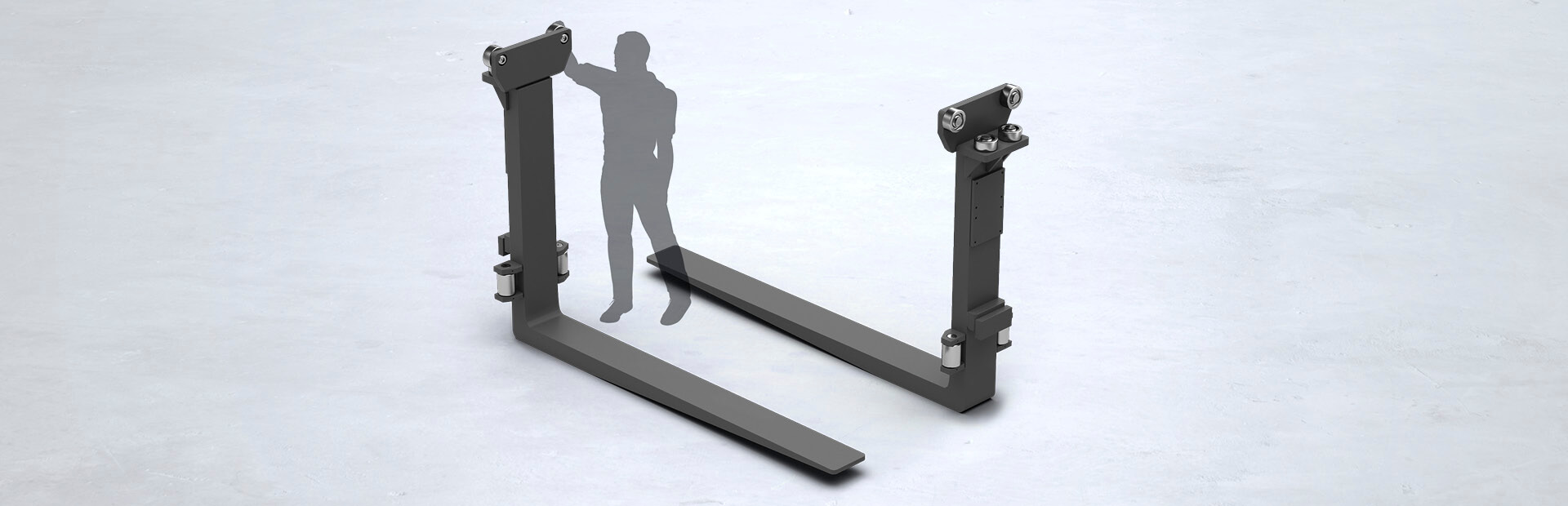

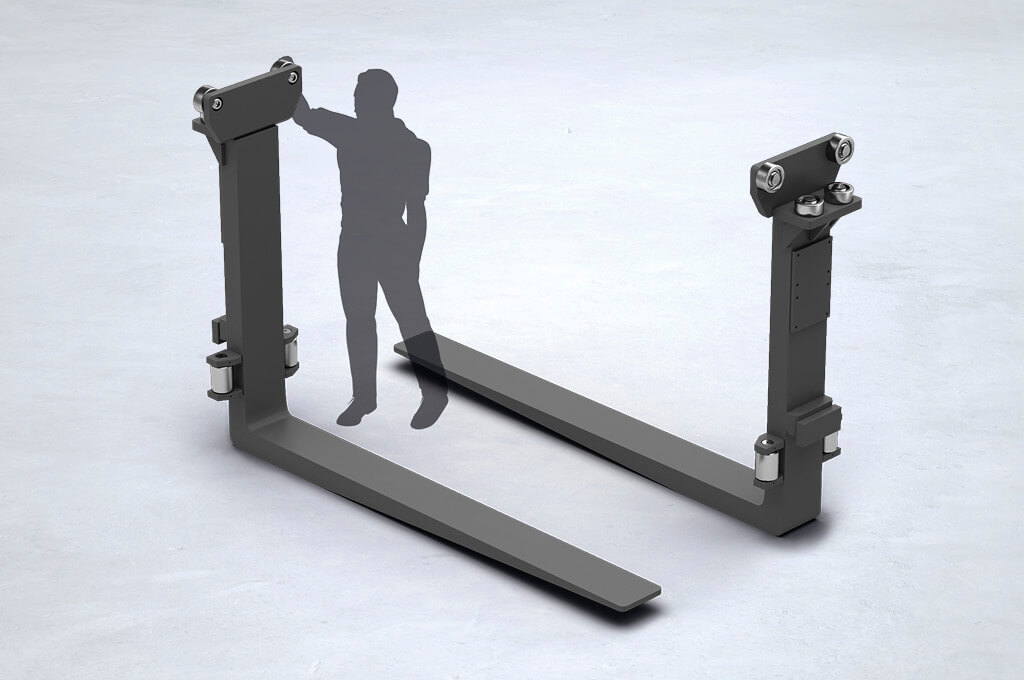

Power packages for safe handling of heaviest loads

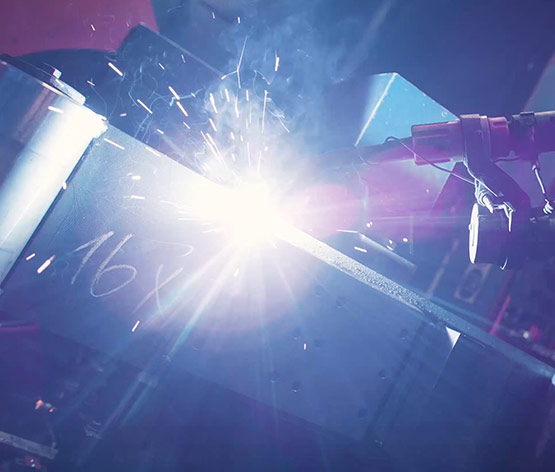

Toughest use, rough environment, around the clock: VETTER BIGForks are first choice as far as efficiency, safety and endurance are concerned. Manufactured on the most modern assembly line for BIGForks and equipped with the competence of the market leader, VETTER BIGForks are benchmarks in terms of quality and performance. The most comprehensive product range offers solutions for almost all applications.

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/f/e/csm_navigation_fork_extensions_689922e615.png)

Share: