Our daily motivation and passion is the development of advanced solutions to improve your safety, precision and efficiency. Working together with you, we are constantly working on new solutions that make VETTER forks even better and perfect for the application.

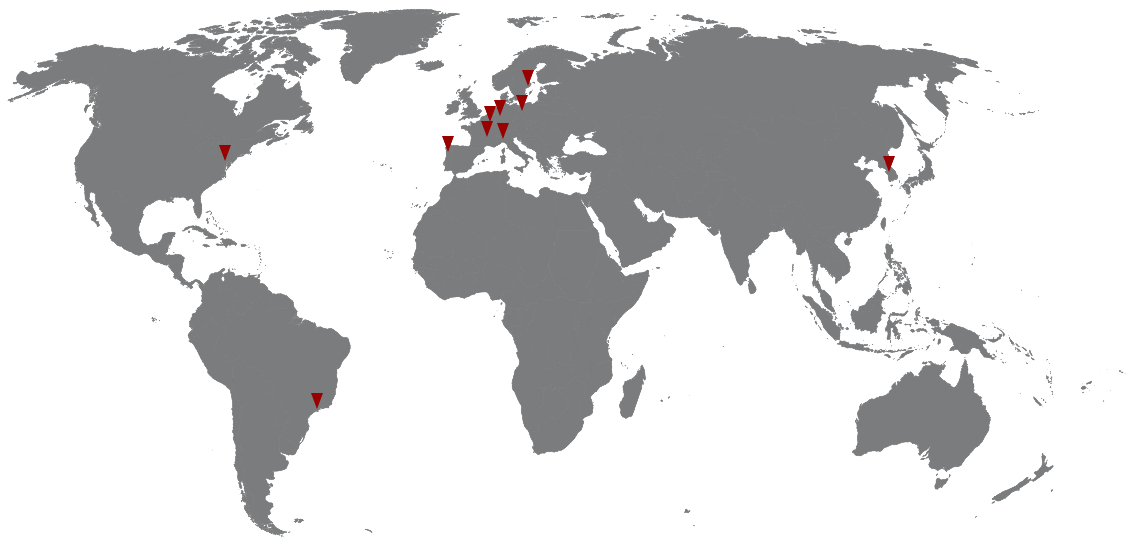

As world-wide leading manufacturer, we have the ability to manufacture forks individually with regard to form, design and quantity to ensure that you remain flexible and are always one crucial step ahead of the competition. The VETTER solutions meet the highest demands on manufacturing quality, reliability and longevity. Always with an eye towards safety during everyday operations.

Stability and safety – over decades. As a family business, we are proud of our independence and autonomy. This gives you the certainty that decisions can be made quickly and directly without being subject to external influences.

Making the best even better is the driving force behind our work. Our declared aim is to contribute our experience, expertise and ideas to new developments that raise your work to the next level. Constant investments, the use of innovative manufacturing processes, uncompromising quality, a sound corporate policy and motivated staff are an absolute necessity for VETTER. These allow us to provide you with the long-term performance that you rightfully expect from us.

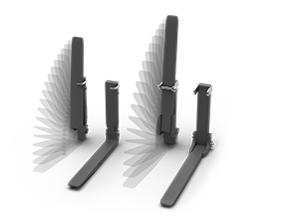

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/f/e/csm_navigation_fork_extensions_689922e615.png)

Share: