Raise the forks!

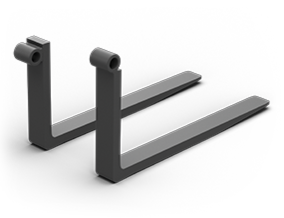

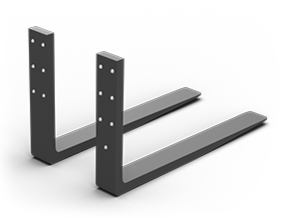

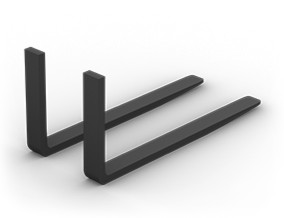

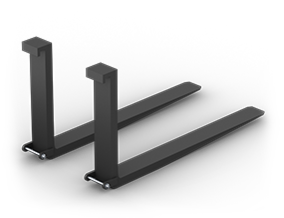

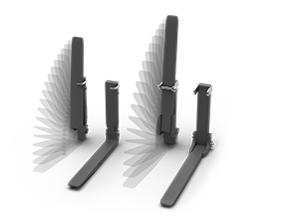

FoldingForks are always sensible when folding up the fork blade can prevent hazardous situations. Furthermore, the space required by the truck can be significantly reduced and manoeuvrability increased. Typical applications are road traffic, outdoor use and restricted spaces.

The engineering and production of FoldingForks are subject to the highest requirements and absolute accuracy. The heel area of a fork is generally the section under the greatest stress. In the case of FoldingForks, the heel area consists of a pin suspension instead of solid material, meaning that utmost attention needs to be paid to this area.

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/f/e/csm_navigation_fork_extensions_689922e615.png)

Share: