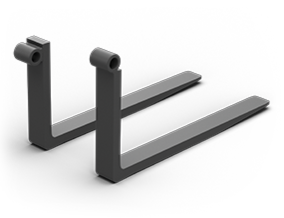

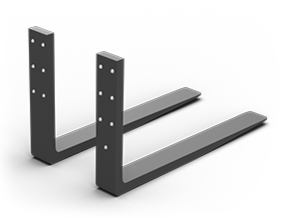

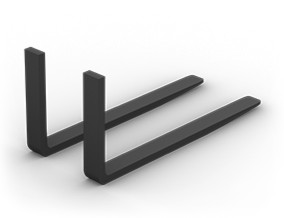

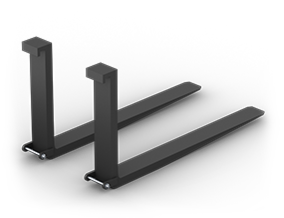

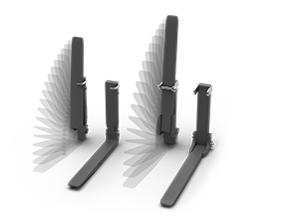

Forks are safety components. They are used on a daily basis to transport goods of considerable value.

Hence, utmost attention should be paid to their inspection.

Note: The use of safe forks, which are in perfect condition, is not only your duty but also an advantage: Working safely means working more economically! Ensuring safety at all times prevents disturbances and guarantees that your equipment is always at your disposal.

Share: