VETTER SmartFork: The Forklift Driver Assistant of the future

17. November 2021 | Smart Solutions

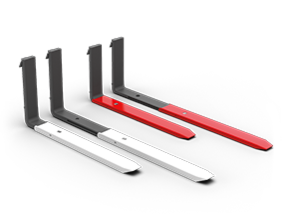

NEARLY 0% TRANSPORT DAMAGES THANKS TO INTELLIGENT SENSOR FORKS

A case study from Robert Thomas Metall- und Elektrowerke GmbH & Co KG, B+K Fördertechnik GmbH aus Lüdenscheid und VETTER Industrie GmbH.

The family company Robert Thomas Metall- und Elektrowerke GmbH & Co KG, worldwide known under the ROTHO brand, is a reliable partner and specialist for qualitative and intelligent equipment for brick drying and concrete block hardening.

For the safe transport of loads they rely on the innovative VETTER sensor fork SmartFork®.

THE INITIAL SITUATION – POOR VISIBILITY FOR THE FORKLIFT DRIVER

“We load and unload trucks for incoming and outgoing goods every day,” says Sebastian Hüttemann, head of Logistics & Quality Management at ROTHO. “We avoid transport damage wherever it is possible. The customer should receive our high quality products undamaged.” To ensure this remains so in future, decision was made in favor of the VETTER SmartFork® with integrated camera and sensor technology as an optimal solution.

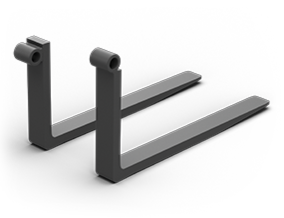

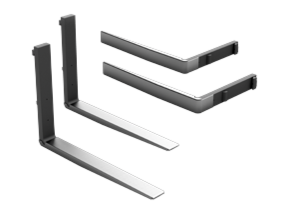

Up to now, ROTHO has used standard forks with a blade length of 1,800 mm for loading and unloading trucks, though without camera or sensor technology. “Our forklift drivers were often driving backwards, because the view was blocked by the load when driving forwards,” declares Sebastian Hüttemann.

THE SOLUTION FOR MORE SAFETY AND EFFICIENCY DURING LOADING PROCESS

Convinced by the VETTER SmartFork® technology, one of the industrial forklifts from the company Robert Thomas was equipped with intelligent high-tech forks: a Hyster Fortens forklift for heavy-duty applications with a 5,500kg load capacity and a Stabau fork positioner, supplied by B + K Fördertechnik GmbH from Lüdenscheid. Up to 90% of the forklift activities apply to loading and unloading trucks, the process of which poses a potential risk of accidents due to obstructed view when the load is picked up.

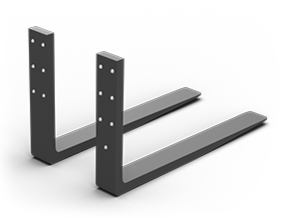

ROTHO decided in favor of the SmartFork® FrontCam, combined with a line laser in the fork tip and the EasySecure sensor in the fork blade. This combination enables safe and efficient loading as well as ergonomic advantages for the forklift driver himself.

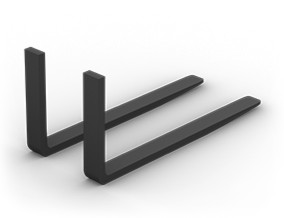

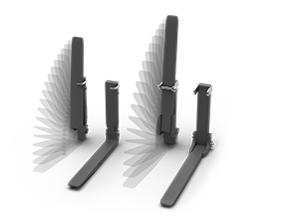

SMARTFORK® FRONTCAM – BEST VIEW TO THE FRONT OF LOADS

With the SmartFork® FrontCam, the driver is able to see everything in front of his forklift, despite loaded cargo. The camera, integrated in the fork tip, transmits the image to a monitor installed in the driver’s cab. The driver’s field of vision is expanded and targeting load carriers is simplified. People and obstacles are noticed early and damages are reduced.

After the first loading processes with the SmartFork®, the enthusiasm of the forklift driver from the company Robert Thomas could not be ignored: “Great, that’s just perfect. When I first heard about the SmartFork®, I immediately said, these forks are interesting and helpful for us.”

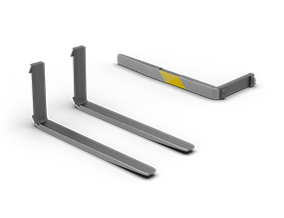

SMARTFORK® LASER – THE PERFECT ADDITION FOR ACCURATE TARGETING OF LOAD CARRIERS

With the laser function as a target aid, in addition to the front camera, loading is even easier and safer. The light source is installed directly in the fork tip, the line laser draws a horizontal line on the load carrier so that the forklift driver can clearly see that he is entering the pallet at the correct height.

SMARTFORK® EASYSECURE – PRECISELY DETECTING THE ENTRY DEPTH

The end of the pallet or the permissible entry depth is recognized by a light sensor in the fork tip, which is signaled to the driver’s cab via LED display.

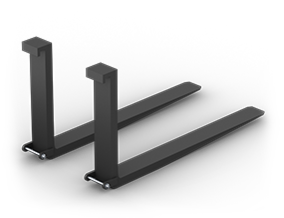

If the forklift operator drives too far into the pallet, the LED display lights up red. This symbolizes that the entry depth has been exceeded, the forks protrude beyond the pallet. By briefly reversing the forklift, the LED display switches to green as soon as the fork tips are flush with the pallet. Lifting of loads behind is avoided, thus transport damage prevented.

According to Sebastian Hüttemann/ROTHO, the interest of his forklift driver about the new sensor forks quickly showed: “We are always intrigued by new technologies, especially those which make our work easier and safer. VETTER SmartForks® are convincing and offer us advantages in our logistics processes.”

SMARTFORK® – THAT’S THE FUTURE

“In combination these three SmartFork® applications are the perfect forklift driver assistant,” says Christof Berg, sales manager at VETTER Industrie GmbH. “The accident statistics of the DGVU are alarming. But together with our customers, the forklift specialists, we ensure safe and efficient logistics with our forks. The developments of the SmartFork® continue, we are dedicated to the forklift of the future. “

All SmartFork® applications described here can be combined with other assistance systems of the SmartFork® product family, which offer many benefits for forklift users.

The integration of intelligent sensors increases safety and productivity, saves time and money and reduces workloads. In addition, the general ergonomic conditions for the forklift driver are significantly improved.

More about VETTER sensor fork SmartFork®:

Related articles

Newsletter

Receive news and updates from the VETTER world by e-mail. Register now without obligation.

Social media

Find updates and news from our social-media channels here: