Remain flexible!

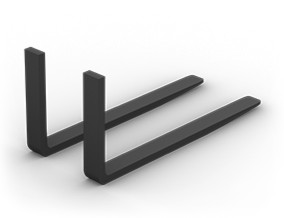

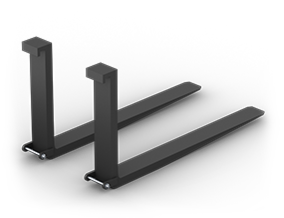

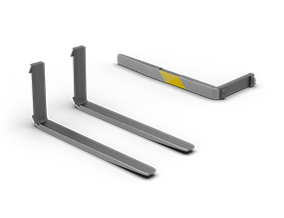

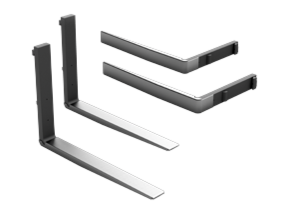

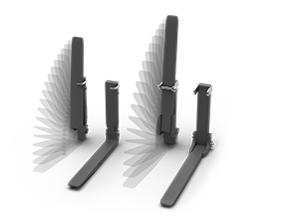

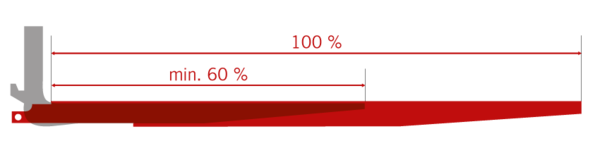

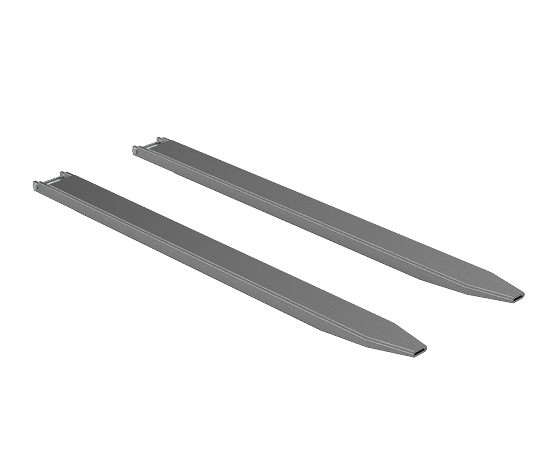

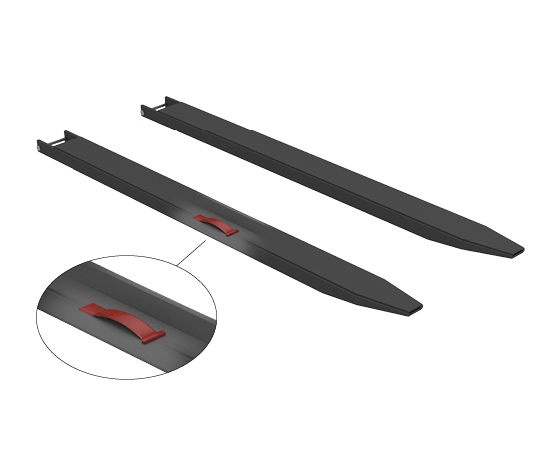

Fork extensions are the ideal solution when occasionally transporting loads that are longer than the forks of the available industrial truck.

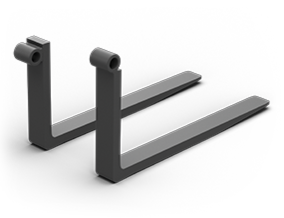

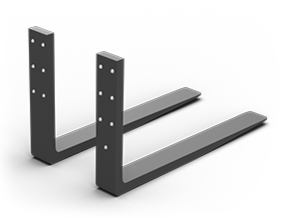

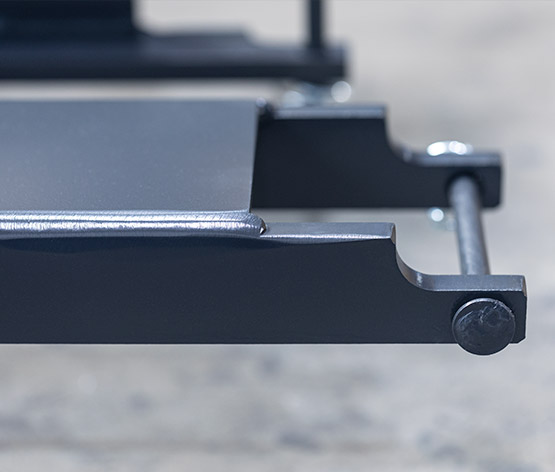

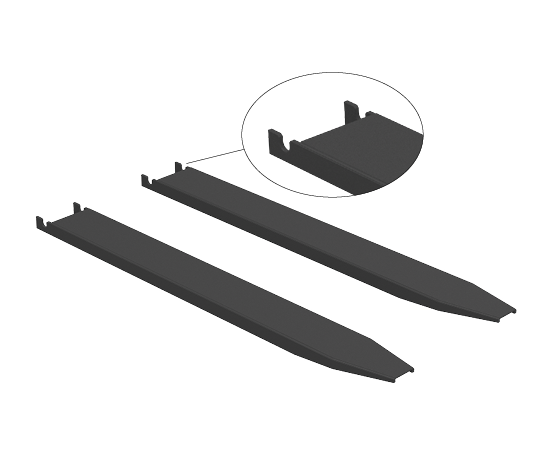

They can be installed quickly and conveniently by sliding them over the existing forks. They are securely locked in place using a locking pin that fits behind the fork shank. All fork extensions conform to ISO 13284.

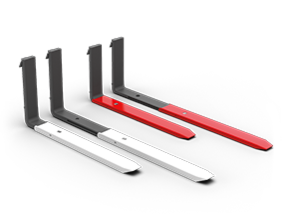

Apart from the open and closed designs, a wide variety of special versions are feasible: coated fork extensions, ATEX versions, fork extensions with special tips and many more besides. Don’t hesitate to contact us!

Share: