Safe transports in hygienic areas

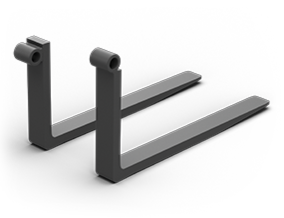

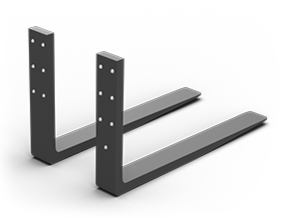

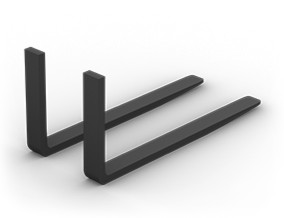

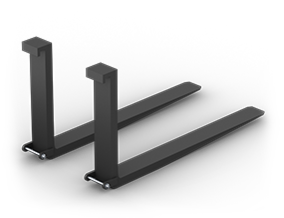

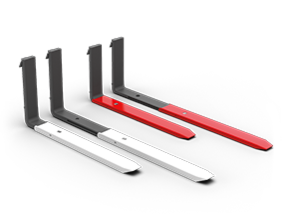

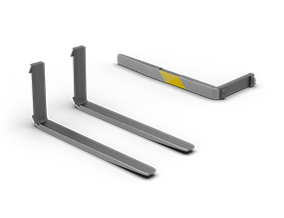

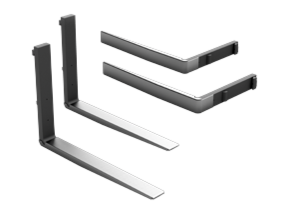

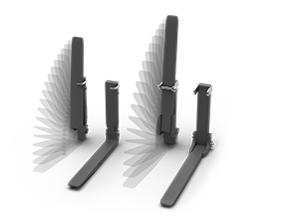

In the food or chemical industry, hygiene is of highest priority. QualityForks with stainless steel cladding are essential for this application! Stainless steel claddings offer an easy to clean, acid-resistance surface to meet highest hygiene requirements and guarantee effective protection against dirt and bacteria. Top-quality workmanship, best materials and utmost diligence guarantee an optimum product.

The fixed cladding on the fork blade and/or fork shank is made of stainless steel (1.4301). The cladding thickness is approx. 4 mm, resulting in an increase in the fork cross-section of approx. 10 mm.

Share: